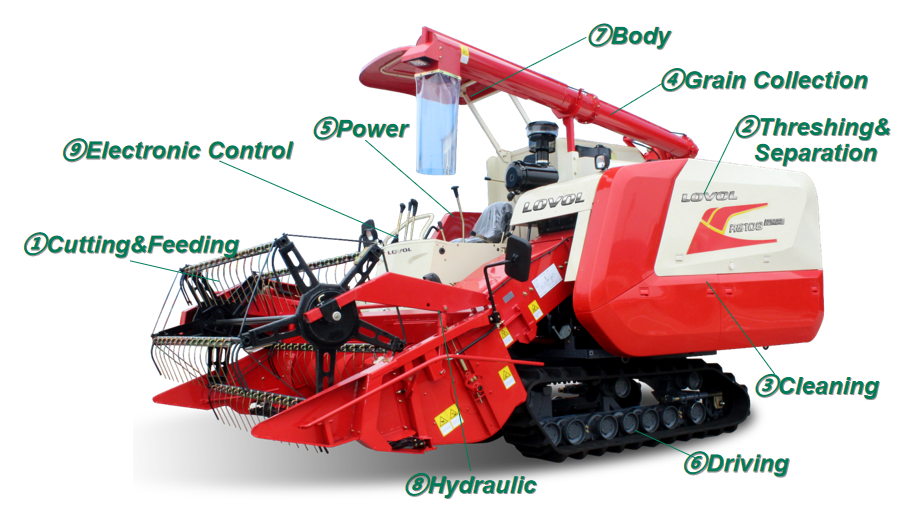

The Main Structures of Lovol Crawler Combine Harvester (Taking RG108 PLUS as an Example)

The Lovol crawler combine harvester is mainly composed of nine modules: header, threshing and separating, cleaning, grain collecting, power, driving, vehicle body, hydraulic, and electronic and electrical systems.

The Lovol crawler combine harvester is mainly composed of nine modules: header, threshing and separating, cleaning, grain collecting, power, driving, vehicle body, hydraulic, and electronic and electrical systems.

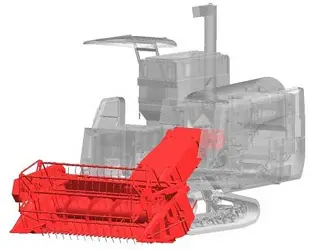

I.Header Module

Including: Reel, Header Frame, Cutter, ReelBracket, Feeding Auger, Divider, Cross the bridge

1.Reel: dial the crops in front of the cutter, assist the cutting knife to cut, and send the cut crops to the cutter table to Feeding Auger.(Support, cutting, conveying)

2.Header Frame: it supports the parts involved in cutting and feeding to complete their own functions, and it is also a material container, and completes the transportation of materials together with the feeding and stirring dragon.

3.Cutter: cut off the crop stalk.

4.Feeding Auger: collect the material cut by the cutter and send it to the bridge.

5. Cross the bridge: send the materials fed to the dragon to the threshing room for threshing.

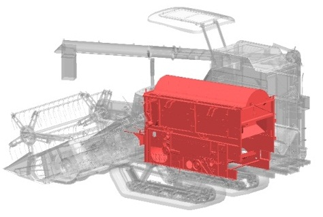

II.Threshing and Separating Module

Including: Threshing Machine Body, Drum Cover, Drum, Concave Plate, Drum Gearbox, Chopper, etc.

The function of the threshing device is to separate grains from ears, and further separate and clean the grains from the threshed materials (composed of grains, ear straws, glumes, impurities, etc.).

1.Threshing Machine Body: It supports various components involved in threshing and cleaning to perform their respective functions, and also serves as a material container.

2.Drum Cover: As a threshing and separating component, it forms a closed material processing container together with the threshing machine body; it guides the materials conveyed into the threshing chamber via the feeder house from the inlet to the outlet, and participates in the threshing and separation of materials.

3.Drum: A core threshing and separating component that combs, beats, and kneads crops to achieve threshing and separation.

4.Concave Plate: A threshing and separating component used to assist the drum in threshing and complete the separation of grains from straws.

5.Chopper: It chops and spreads the threshed materials discharged from the drum to realize straw returning to the field.

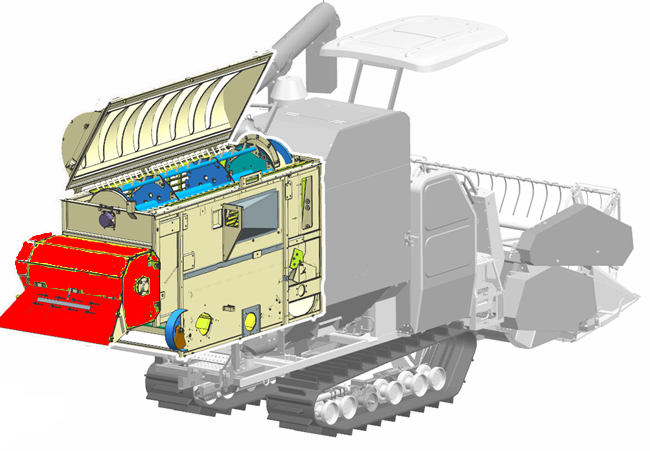

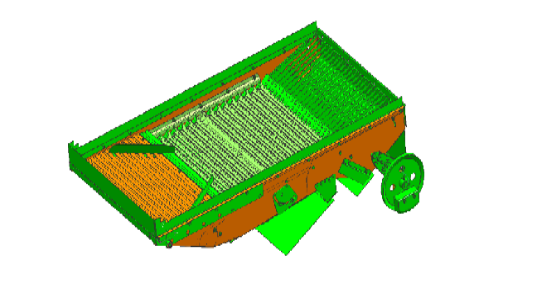

III.Cleaning Module

Function of the Grain Cleaning Device:

To separate the grains from the mixture and discharge other impurities out of the machine, so as to obtain clean grains.

2.Fan:As a cleaning component, it works in conjunction with the cleaning sieve on the materials falling from the concave plate to ensure the materials are thoroughly cleaned.

1.Cleaning Sieve:As a cleaning component, it works in conjunction with the fan to screen and purify the materials falling from the concave plate. support - from day one to long after your purchase.

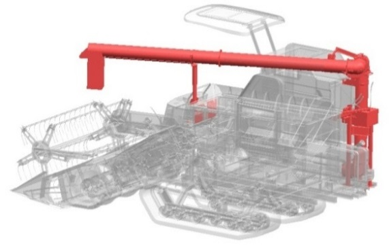

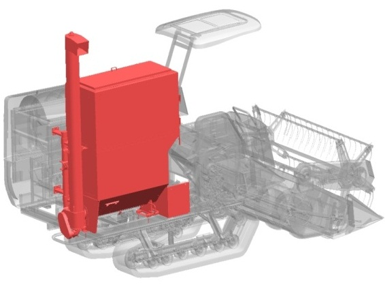

IV.Grain Collection Module

1.Impurity Re-thresher: It re-threshes the materials that are not fully threshed or cleaned, and conveys them to the sieve surface for secondary cleaning.

2.Grain Unloading Tube: A grain unloading mechanism used to unload the grain in the grain tank into grain bags or transport vehicles.

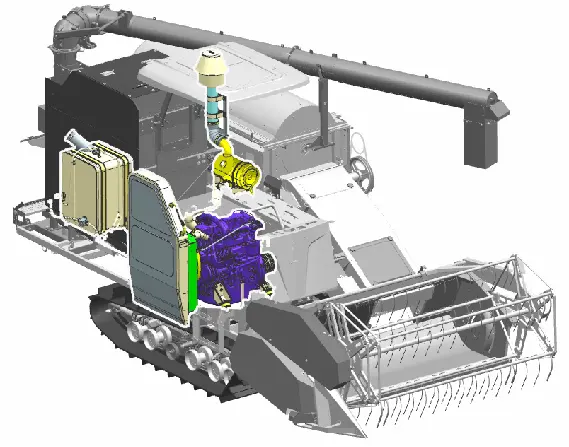

V. Power Module

1.Engine: As the power source of the entire machine, it provides power and transmits the power to various working components through the transmission system.

2.Air Filter: It filters dust, sand particles and other impurities in the air to ensure sufficient and clean air enters the engine.

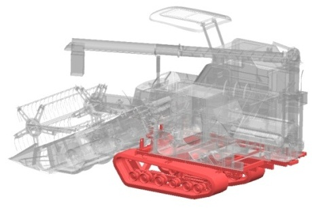

VI.Driving Module

Including: Chassis Frame, Transmission Control, Clutch Control, Brake Control, Working Device Control, Steering Mechanism, Wheel Assembly, Track, Gearbox, Brake Device, Transmission Case.

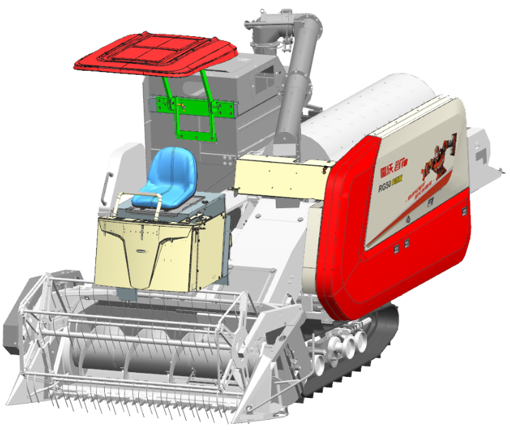

VII.Body Module

Including: Cab, Operator Console, Seat, Shield, Rearview Mirror, Rear Cover, Toolbox, Access Ladder (for Cab), Heater, Air Conditioner, Maintenance Ladder.

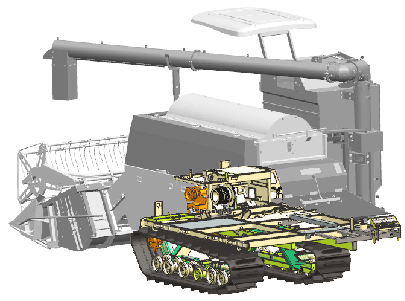

VIII.Hydraulic Module

Including: Header Lifting, Hydraulic Steering, Multi-way Valve, HST (Hydrostatic Transmission), Gear Pump, Hydraulic Cylinder, Motor, Filter, Radiator, Oil Tank, Pipelines.

IX.Electronic Control Module

Including: Console Wiring Harness, Lighting Wiring Harness, Grain Tank Wiring Harness, Header Wiring Harness, Engine Wiring Harness, Storage Battery, Cab Wiring Harness.