I.Maintenance Step 1: Condenser air inlet grille, air conditioning filter blockage, and compressor belt failure

Condenser air inlet grille

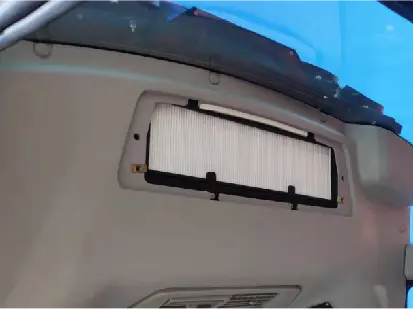

Evaporator filter

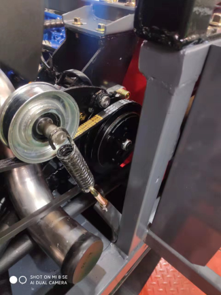

Compressor belt

When the crawler machine is operating, check the dust accumulation on the condenser air inlet daily and remove dust and straw; regularly inspect and clean the filter element at the evaporator weekly; adjust the compressor belt tension monthly (press the middle of the belt with a force of 18N, deflection 10mm).

II.Maintenance Step 2: Electrical Circuit Inspection

Condensing fan

Evaporation Fan

Compressor clutch

For AC system not cooling fault, follow the 'two rotations and one engagement' principle, that is, the evaporator fan and condenser fan operate, and the compressor clutch engages. Ensure the above components are functioning properly before checking the wiring and fuse.

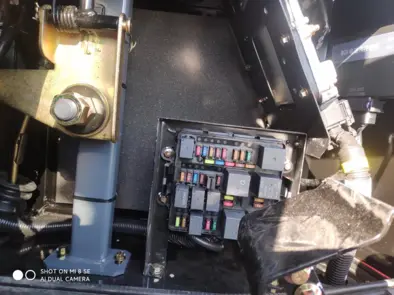

80A Insurance

30A Insurance

AC relay assembly 40A Insuranc

First, check the entire machine for electrical circuit faults. According to the circuit diagram, start by inspecting the 80A fuse related to the air conditioner at the battery, then check the 30A fuse at the fuse box, and finally check the 40A fuse at the air conditioner relay or relay assembly to ensure there is no damage.

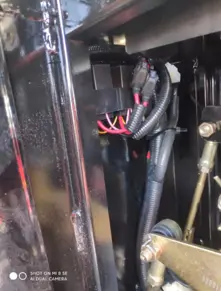

AC power wiring harness

Condenser control switch

Control panel switch harness

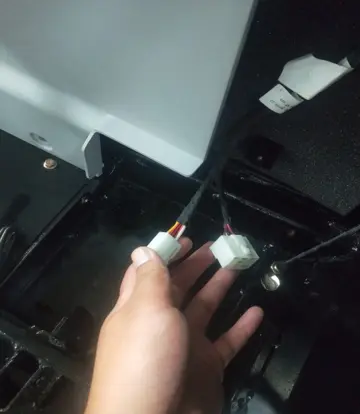

With all types of fuses and relays confirmed to be in good condition, please check each connector to ensure the plugs are fully inserted and that the wiring harness pins are not loose.

III.Maintenance Step 3: Refrigerant Leak or Insufficiency

AC switch and evaporator fan speed control switch

Idle speed shows 850 RPM

After the AC runs, it operates at 810 RPM

Start the engine and let it idle, turn on the evaporator fan switch, and adjust the temperature control knob to the maximum. Observe the engine speed; if the load rate does not change, the air conditioning pipes or refrigerant need to be checked. When the air conditioning system is working normally, the engine will increase fuel injection, which can be clearly felt as increased vibration in the cabin.

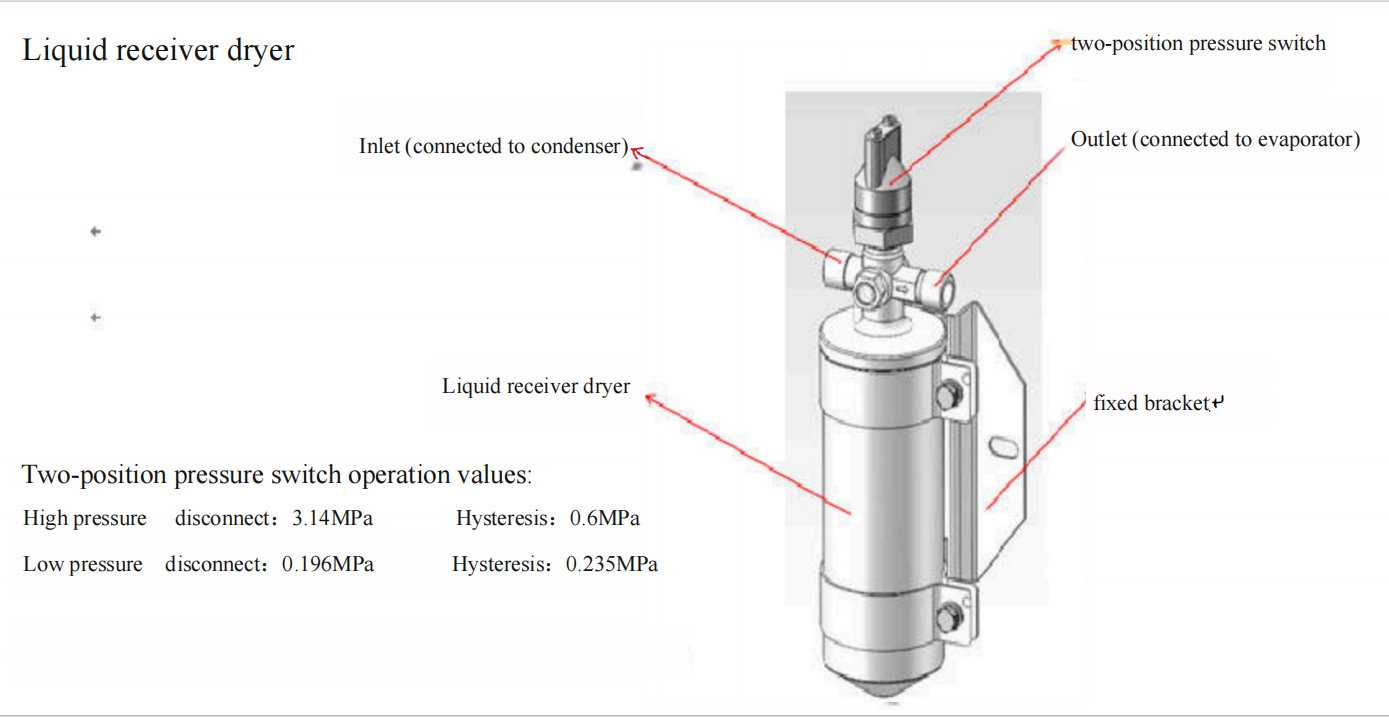

By observing the sight glass of the liquid storage type dryer, the amount of refrigerant in the system can be determined: When the engine is idling and the air conditioner is just turned on, a few bubbles appear initially; after accelerating, the bubbles disappear and the sight glass becomes clear, indicating the refrigerant is just right. If the sight glass remains clear upon startup, it indicates excess refrigerant. If bubbles are always present, it indicates insufficient refrigerant. If the sight glass appears cloudy, it means there is moisture in the system and a vacuum re-pump is needed.

By inspecting the joints of the air conditioning pipes, as well as the compressor, condenser, evaporator, and dryer for oil stains, you can determine whether each air conditioning pipe is leaking. You can also spray foam water on these components to check for leaks, and replace the corresponding parts once a leak is found.

IV.Maintenance Step 4: Dirt blockage in the air conditioning system

The air conditioning system is functioning normally, but it is not cooling. There is frost and condensation on the dryer, expansion valve, and front and rear pipe connections, and the condenser is not heating up. The sight glass shows no flow of Freon; it is completely still. Solution: Discharge the system's Freon, check if it is blocked by dust or debris, replace the dryer, expansion valve, condenser, and hoses, and recharge with refrigerant oil and Freon (preferably replace everything).

V.Maintenance Step Five: Air Conditioner Compressor Malfunction

The compressor is a core component of the air conditioning system. Market compressor failures are mainly due to the compressor clutch not engaging. The compressor is replaced in situations such as when the air conditioner is not cooling, system low-pressure is high, the compressor makes abnormal noises, or the compressor leaks refrigerant.

VI.Maintenance Step 6: Malfunctions of the liquid storage dryer, evaporator assembly, and condenser assembly

Reservoir type dryer

Evaporator Assembly

Condenser assembly

The liquid storage dryer, evaporator assembly, and condenser assembly are important components of the air conditioning system. They should be replaced if the air conditioning does not cool, there is moisture in the system, the evaporator is iced up, or the condenser is leaking refrigerant.