1.Clean the dust and grass clippings on the radiator

As harvesters work environment is relatively bad,when harvesting there are lots of dust and grass clippings.The radiator will be filled with grass clippings and the dust will affect the cooling of water tanks.So it needs to be cleaned up before each operation,which is best cleaning by two times in each shift.

As harvesters work environment is relatively bad,when harvesting there are lots of dust and grass clippings.The radiator will be filled with grass clippings and the dust will affect the cooling of water tanks.So it needs to be cleaned up before each operation,which is best cleaning by two times in each shift.

2.Perform a maintenance according to the air filter instructions

The maintenance method is as follows:

The maintenance method is as follows:

①Remove the paper filter elements and tap the surface or sweep off the surface dust with a soft brush;

②If conditions available remove dust by the method that(0.4-0.5)Mpa compressed air flushes filter elements back;

③Do not use any oil or wate to clean the paper filter elements.

Note:

When the paper filter elements are maintained by(2-3) times or the assembly resistance is still more than 6 Kpa after the maintenance,they shall be replaced with new filter elements;if the paper filter elements are replaced by (2-3) times,the safety elements shall be replaced once and the inside of the air filter shall be cleaned.

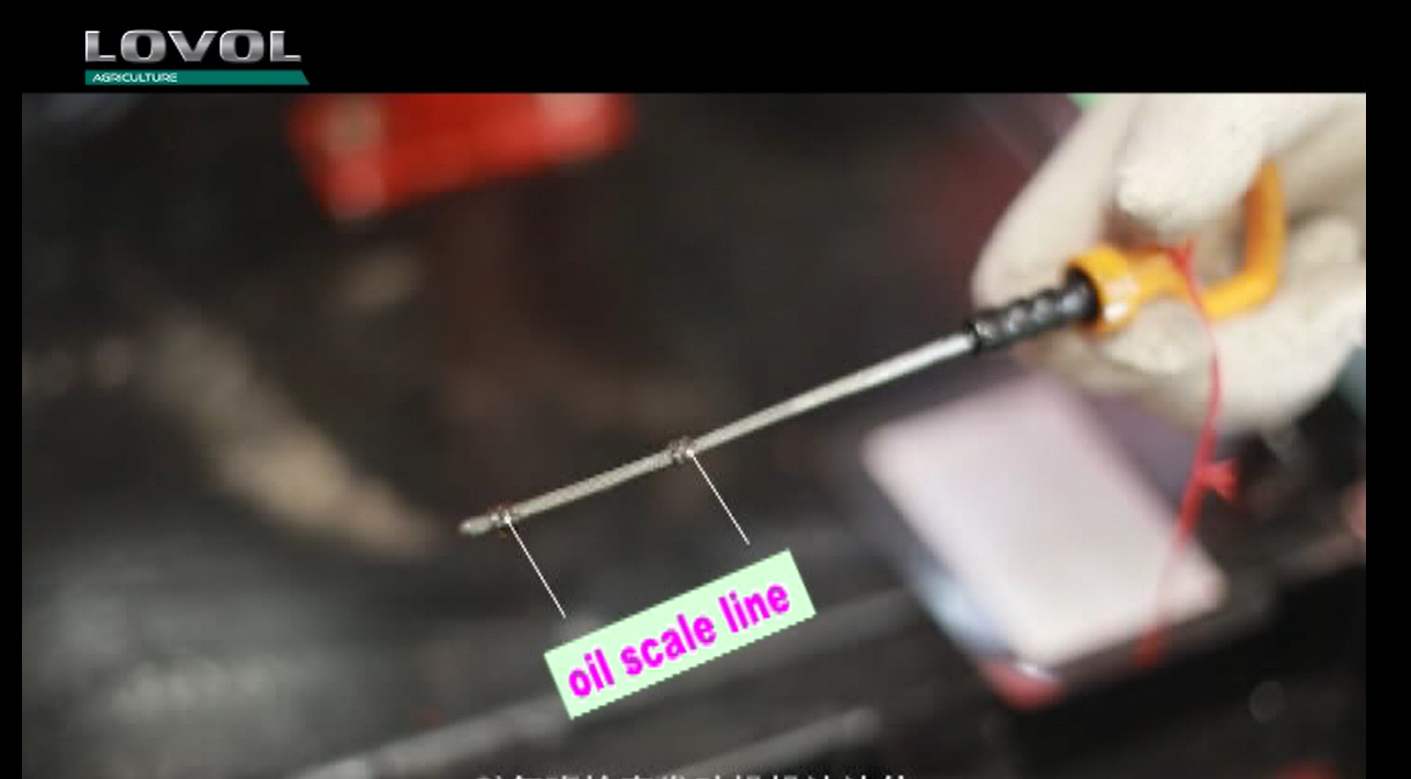

3.Check the engine oil level in each shift